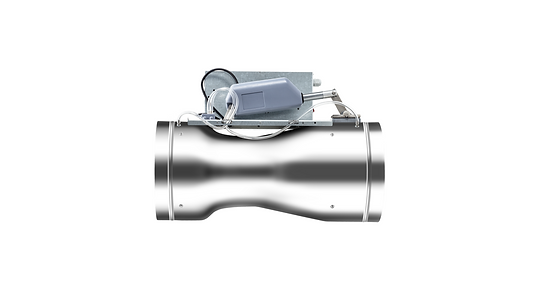

UVA-Universal Venturi Valve

Kaseman UVA is a Variable Air Volume (VAV) venturi valve specifically designed for critical space ventilation requirements, where infection control, energy savings, and reduced maintenance costs are important considerations.

It can help:

-

Reduce infection risks in spaces that require asepsis, such as operating suites, burn units, intensive care units, bio-lab research facilities, or pharmaceutical processing areas.

-

Maintain cascading pressurization to protect spaces such as airborne infectious isolation rooms, protective environment rooms, pharmacies, and laboratories

UVA Valve

With its fast actuation and pressure-independent mechanism, UVA can compensate for changes in static pressure in less than a second and maintain an accuracy of 5% of the target airflow rate as long as the differential pressure across the valve is between 150 and 750 Pa.

Each UVA is calibrated and has its own airflow curve up to 48 points. It maintains an offset between the volume of air supplied into and exhausted from a space to ensure reliable room pressurization and directional airflow.

Kaseman UVA supports 0-10V or Modbus signals to adjust the desired airflow, and is also available for 2-state control.

Features & Benefits:

-

Pre-calibrated in the factory: Reduces commissioning time in the end market.

-

Pressure-independent valve: Avoids rebalancing costs.

-

Mechanical design flexibility means valves do not require straight duct runs upstream or downstream.

-

No flow sensors to maintain: HVAC system requires fewer controllers and dampers.

-

High turndown ratios up to 20:1, helps reduce energy costs.

-

Modbus RTU can interface with Modbus signal-capable BMS, providing flexibility to handle changes in space configuration.

-

Supports 0-10V, Modbus signals, or 2-state control to meet any project's desired airflow requirements. Also Can be programmed with a pandemic mode for rapid room isolation.