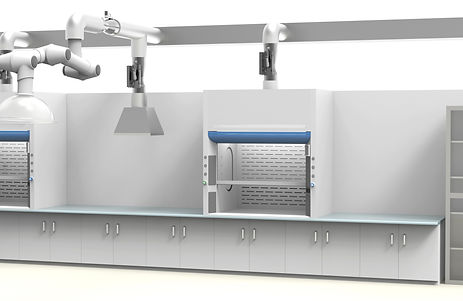

VVA kits - Fume hood control kits

Kaseman VVA kits are the desired solution for fume hood face velocity control, designed to meet ventilation requirements in life science lab facilities. They provide a safe and comfortable working environment for research in a single standalone lab or an entire research complex.

These kits include programmed VVA venturi valve, sash sensors, occupancy sensors, and a fume hood monitor. The setup process is user-friendly for unskilled workers, allowing them to easily calibrate, set alarm and operation set points, and control the system.

These kits offer

-

Flexibility, airflow turndown, and additional configuration options, making them an ideal solution for modular mixed-use facilities.

-

With visible working states and VVA fast responses to changes in airflow, it effectively controls ventilation zones and achieves energy savings, thereby reducing maintenance costs.

-

Easy integration of additional sensors and devices to record data from the experiment.

VVA kits - Fume hood control kits

Life science research spaces designed with an open lab and fume hood require a unique ventilation control solution. As airflow or pressurization requirements change, the impact on adjacent spaces such as work areas, offices, and common corridors directly contributes to the balance of the entire lab.

VVA kits can precisely exhaust the desired airflow through pre-integration with the fume hood exhaust flow control system. This integration enables the control of proper fume hood exhaust airflow rates based on sash opening positions, detection of fume hood usage occupancy, display of various fume hood operation data, and comprehensive delivery of an ideal fume hood operation environment.

At the heart of the system is the venturi valve offering mechanical pressure independence to maintain stable, precise airflow control.

VVA kits with VVA Venturi valve

-

Can compensate for changes in static pressure in less than a second

-

Maintain an accuracy of 5% of the target airflow rate as long as the differential pressure across the valve is between 150 and 750 Pa.

-

High turndown ratios up to 20:1

-

Supports 0-10V or Modbus signals to adjust the desired airflow, and is also available for 2-state control. With its fast actuation and pressure-independent mechanism.

VVA Kits's Features & Benefits:

-

No flow sensors to maintain.

-

Flexibility to handle space configuration changes

-

Support configuration for all valve sizes

-

Enhanced fume hood control

-

Operator safety

-

Clearer way to watch and manage your critical environment facility